Special products

Special products in our foundry are scorifiers from following steel grades:

Recommended for melting crucibles and crucibles for salt baths to be used in carburizing or sulphur medium. Operating temperature 1200°C.

Recommended for melting crucibles and crucibles for salt baths operating in carburizing or sulphur atmosphere. Operating temperature 1000°C.

Is suitable for melting crucibles and crucibles for salt baths. Operating temperature 1150°C.

Recommended for pouring and batched crucibles for fused basalt. Operating temperature 1200°C.

Resistance of the crucibles

The crucibles are resistant to nitrides, less resistant to chlorides, sulphides and cyanides. The usual metal baths, except for lead baths, melt the iron. This feature is not desirable e.g. for baths of aluminium and its alloys because it may effect the purity of the molten metal. The crucibles made from chromium-nickel steels have proved successful for molten copper and its alloys.

In the lead bath, only litharge on the bath surface may cause corrosion. Therefore, we recommend to apply a plain iron sheet as a protective band on such places. The crucibles made from plain steels are prone to scale formation. If the scales fall on electrical heating coils, they can disturb operation or destroy the coils. Therefore, it is recommended to apply the alloy steel crucibles for heating purposes.

The chromiumnickel steel crucibles are very sensitive to gases bearing sulfur compounds, reduction gases and carburizing substances. The sensitivity of the crucible increases with an increase in nickel content and temperature. The chromium steel crucibles are best resistant to the effect of all these influences.

Service Life of the crucibles

t depends substantially on the operation conditions and on proper handling during operation. The crucibles made from plain steels have the shortest service life. However in some cases they may be very economical. The service life of the crucible may be considerably lower in the following cases:

When heating by gas, it is necessary that the flames be directed tangentially towards the crucible wall. In addition to this, heating with excess air, which may form oxidizing flames, should be avoided. Local overheating can be avoided by periodically turning the crucible. When heated from below, a protection shield should be installed under the crucible so that overheating does not occur.

When the crucible is heated and cooled very often, it may become very scaled and this may impact its ser- vice life, especially in case of plain steel crucibles. The crucible should be continuously held at a temperature that enables the salt to remain liquid.

Too rapid heating is not enough to molten content of the crucible was able to absorb the transferred heat evenly and it may happen that the crucible overheats and breaks. At the same time, scales form quickly on the interior. It is recommended, therefore, that the crucible should be emptied after finishing the work and when using it again, the crushed salt should be melted gradually.

The deposits act as insulation which causes accumulation of heat at the bottom and, hence, strong scaling. Thus the salt bath is exposed to the danger of decomposition. Therefore, the crucible must be thoroughly cleaned from time to time.

This has an especially damaging impact on crucibles made from plain steels. During hardening and tempering, the bath should contain more than 5% cyanide and more than 3% cyanide when tempering. The lower salt concentration may cause corrosion, and the iron trioxide or iron monoxide (sponge iron) is separated and set on the bottom of the crucible thus lowering its service life.

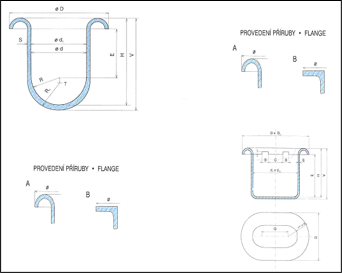

Round crucibles

| č. modelu Casting Pattern-No. | Obsah Volume I | Váha Weight kg | H | Průměr Diameter d1 | V | Průměr Diameter d | Průměr Diameter D | r | r1 | s | R | R1 | T | E | Příruba Flange |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 21964 | 2,5 | 19 | 250 | 140 | 270 | 170 | 260 | 15 | 30 | 15 | 70 | 85 | 5 | 150 | A |

| 21736 | 6 | 42 | 300 | 190 | 325 | 230 | 350 | 20 | 40 | 20 | 95 | 115 | 5 | 165 | A |

| 21718 | 14 | 75 | 450 | 230 | 475 | 270 | 410 | 25 | 45 | 20 | 115 | 153 | 5 | 290 | A |

| 40125 | 14 | 64 | 280 | 300 | 300 | 340 | 435 | 20 | 142 | 162 | B | ||||

| 21886 | 17 | 75 | 350 | 300 | 375 | 340 | 500 | 30 | 50 | 20 | 150 | 170 | 5 | 150 | A |

| ETE-1730 | 18 | 120 | 500 | 225 | 535 | 275 | 500 | 40 | 65 | 25 | * | * | * | * | A |

| B-81787 | 18 | 72 | 490 | 245 | 510 | 285 | 400 | 20 | 115 | 135 | B | ||||

| 41427 | 19 | 127 | 620 | 220 | 650 | 280 | 460 | 30 | 60 | 30 | 210 | 240 | A | ||

| T-285 | 21 | 40 | 335 | 260 | 350 | 290 | 400 | 15 | 120 | 135 | B | ||||

| 21740 | 32 | 105 | 550 | 300 | 580 | 340 | 500 | 30 | 50 | 20 | 150 | 170 | 10 | 350 | A |

| 21667 | 35 | 155 | 500 | 350 | 535 | 400 | 570 | 30 | 55 | 25 | 175 | 200 | 10 | 270 | A |

| 22585 | 38 | 150 | 580 | 290 | 615 | 340 | 510 | 30 | 55 | 25 | 145 | 170 | 10 | 380 | A |

| KM-001 | 48 | 160 | 520 | 405 | 475 | 450 | 590 | 22 | 174 | 220 | 6 | B | |||

| ETE-1731 | 55 | 220 | 500 | 400 | 535 | 460 | 680 | 40 | 70 | 30 | * | * | * | * | A |

| 323 | 55 | 140 | 530 | 380 | 550 | 420 | 585 | 20 | * | * | * | * | B | ||

| 22903 | 66 | 240 | 800 | 350 | 835 | 400 | 570 | 30 | 55 | 25 | 175 | 200 | 10 | 570 | A |

| 1-1781 | 75 | 195 | 720 | 440 | 750 | 475 | 600 | 20 | 170 | 190 | B | ||||

| 21668 | 75 | 225 | 500 | 520 | 535 | 570 | 740 | 30 | 55 | 25 | 260 | 285 | 10 | 185 | A |

| 20391 | 90 | 175 | 630 | 535 | 660 | 575 | 700 | 20 | 230 | 250 | B | ||||

| ETE-1729 | 95 | 320 | 550 | 510 | 590 | 570 | 790 | 40 | 70 | 30 | * | * | * | * | A |

| ND-1260 | 140 | 290 | 475 | 700 | 540 | 900 | 30 | 350 | 380 | B | |||||

| ETE-1732 | 140 | 435 | 800 | 510 | 840 | 570 | 790 | 40 | 70 | 30 | * | * | * | * | A |

| 22469 | 140 | 355 | 800 | 520 | 835 | 570 | 740 | 30 | 55 | 25 | 260 | 285 | 10 | 485 | A |

| ND-1259 | 240 | 560 | 660 | 780 | 730 | 850 | 1000 | 35 | 380 | 415 | B |

*) lenticular bottom

Oval crucibles

| č. modelu Casting Pattern-No. | Obsah Volume I | Váha Weight kg | D x Da | d x da | d1 x d1a | r | r1 | r2 | s | E | H | V | G | C | B | F |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ETE-1512 | 89 | 320 | 770 x 570 | 610 x 410 | 550 x 350 | 25 | 55 | 80 | 30 | 535 | 600 | 640 | 200 | 258 | 80 | 25 |

| 22774 | 105 | 220 | 800 x 600 | 610 x 410 | 560 x 360 | 35 | 60 | 70 | 25 | 535 | 600 | 625 | 200 | 250 | 90 | 30 |

| ZS-196 | 150 | 420 | 920 x 720 | 760 x 560 | 700 x 500 | 25 | 55 | 80 | 30 | 535 | 600 | 640 | 200 | 200 | 80 | 25 |

| 22622 | 195 | 290 | 970 x 760 | 770 x 560 | 730 x 520 | 40 | 60 | 90 | 20 | 560 | 620 | 640 | 210 | 320 | 75 | 20 |